Why Correct Box Dimensions Matter

Packaging is more than just covering your products. The right box size protects your goods, reduces costs and impresses customers. Measuring a box incorrectly might seem like a small error, but it can cost you higher shipping fees, damaged items and unhappy buyers. Therefore, for every business, whether small or large, the length width height calculation is a key part of packaging.

Accurate dimensions help you save money, reduce storage waste and ensure that your product looks professional when delivered. That is where we come in. At Package Perfection, we are here to make this calculation easier for you. So, if you’ve ever wondered why your shipping bill looks inflated or why your products don’t fit perfectly in their boxes, the answer often lies in wrong measurements. Let’s break down how you can measure your Custom packaging the right way.

Understanding Box Dimensions in Simple Terms

When you hear the term length width and height, it refers to the three measurements that define the size of a package. Each dimension plays a role in both shipping and product protection.

- Length is always the longest side of the box, usually front-facing.

- Width is the shorter side of the base, perpendicular to the length.

- Height (sometimes called depth) measures from the bottom to the top.

In packaging, the correct order of dimensions is always L × W × H. This standard avoids confusion when you place orders with manufacturers or shipping companies. For example, if your box measures 20 inches long, 10 inches wide, and 6 inches high, it will always be listed as 20 × 10 × 6.

At Package Perfection, we understand that clarity matters. Therefore, by keeping these terms consistent, we help businesses like yours avoid costly mistakes when designing custom packaging.

How to Measure Length Width Height Box Correctly Without Stress

Accurate measuring doesn’t require special skills but it does need the right tools and a little care. To measure a box length width height, you’ll need a tape measure, a ruler or even a digital caliper if precision is essential.

Here is a simple step-by-step guide:

- Place the box on a flat surface.

- Measure the inside dimensions if you want to know how much product it holds.

- Measure the outside dimensions if you’re calculating shipping.

- Record all numbers in either inches or centimeters and stick to one unit.

For example, if the inside length of your box is 18 inches, the width is 12 inches, and the height is 8 inches, then your inside measurement is 18 × 12 × 8. That number helps you know the product fit, while outside dimensions help you estimate shipping costs. Furthermore, we recommend keeping a record of your measurements in a chart to make ordering packaging easier next time.

Inside vs. Outside Dimensions: Which One Matters More?

When dealing with a box length width height , it’s important to know the difference between inside and outside measurements.

Inside dimensions tell you how much space is available for your products. These numbers ensure that your items fit snugly without being damaged.

Outside dimensions are more about logistics. They determine how the box fits in trucks, warehouses and on shelves.

Mixing these two measurements can cause major issues. Imagine ordering packaging that seems perfect for your product, only to find that the actual usable space inside is too small. On the other hand, if you only consider inside measurements, you may underestimate shipping costs because carriers often use outside dimensions.

At Package Perfection, we recommend noting down both sets of dimensions. This simple step can save you from expensive errors in shipping and product safety.

Common Mistakes You Should Avoid

Measuring a length width height box seems easy, but there are common mistakes that businesses often make. These errors can increase costs and create unnecessary stress.

- Measuring from outside edges when you need the inside dimensions.

- Confusing width with height, especially in taller boxes.

- Forgetting to include space for padding or inserts.

- Ignoring the need to round up dimensions for shipping carriers.

Each of these mistakes might appear small, but together they can add up to lost money and wasted resources. The good news is that avoiding them is simple. Take your time, double-check your numbers and don’t hesitate to ask for professional help. That’s where our team at Package Perfection steps in. We can review your measurements and guide you to ensure accuracy before you place an order.

Why Accuracy in Dimensions Saves You Money

Shipping companies such as FedEx, UPS and DHL base their charges not only on weight but also on size. This means that a box length width height calculation directly affects your shipping bill. If your measurements are even slightly wrong, you may face higher charges or rejected shipments.

Using custom drone packaging boxes helps avoid such issues by ensuring every product fits perfectly according to carrier size standards. Correct dimensions also mean better use of storage space. Warehouses and retailers rely on accurate box sizes to stack and store products efficiently. Thus, a miscalculation can lead to wasted space, increased costs and even damaged goods.

Dimensional Weight (DIM) Factor Explained

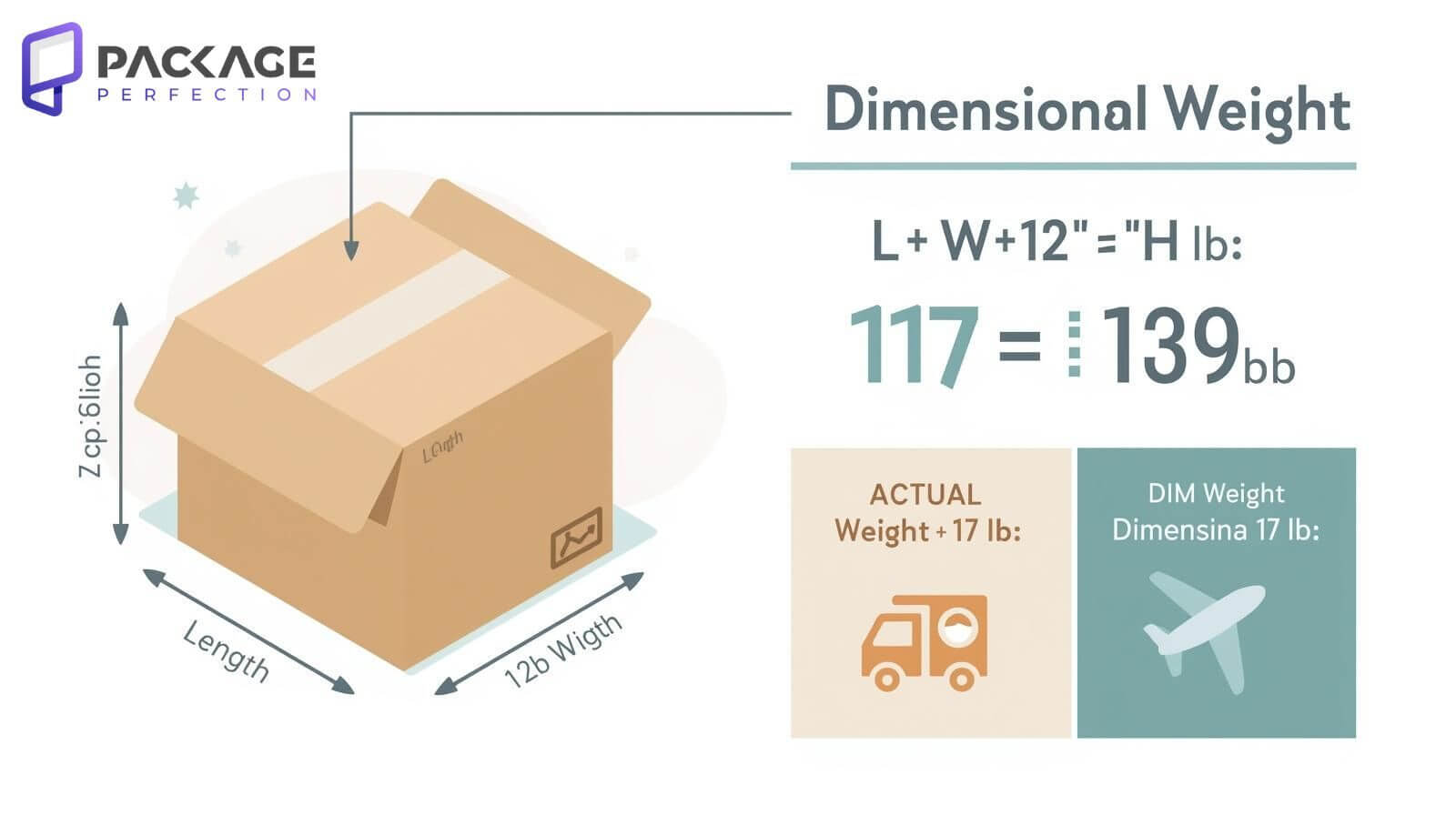

You need to know about dimensional weight to understand why box size matters so much. Carriers calculate it using formula

(Length × Width × Height) ÷ DIM Divisor

For FedEx and UPS, the DIM divisor is usually 139 for domestic and international shipments. This means that even a lightweight product can cost more to ship if the box is large.

For example, a box measuring 20 × 12 × 10 equals 2400 cubic inches. Divide this by 139, and you get about 17 pounds. Even if the actual weight is just 5 pounds, you’ll be charged for 17 pounds.

This is why getting your box length width and height measurement correct matters. A box that is only slightly bigger than necessary could triple your shipping costs.

Practical Tips From Package Perfection

We at Package Perfection want to make measuring easier for you. Here are some practical tips you can apply right away:

- Always measure twice for accuracy before recording dimensions.

- Use a box-sizing chart or calculator to avoid mistakes.

- If your product is fragile, add extra space for bubble wrap or inserts.

- Label your recorded dimensions clearly when sending them to suppliers.

Our goal is to help businesses like yours avoid packaging stress. With our wholesale rates, free USA shipping, and fast delivery, we ensure that your brand gets packaging that fits perfectly and ships affordably.

Let Us Help You With Your Box Dimensions

Correct box dimensions are more than numbers. They save you time, reduce costs and build trust with your customers. At Package Perfection, we are always ready to help you calculate the right box length width and height for your products.

We make every type of box at wholesale rates and ship most orders within 7–10 business days. Our services extend beyond the USA, ensuring that businesses worldwide can benefit from packaging that looks professional and performs reliably. If you ever feel confused while measuring dimensions, reach out to us. Our team will gladly guide you and ensure you get product packaging that suits your needs perfectly.

FAQs

Q1: What does a box length width height mean?

A. It refers to the three measurements used to describe a box: length, width and height, always listed in that order.

Q2: Do I measure inside or outside dimensions?

A. Measure inside for product fit and outside for shipping purposes. Both are important.

Q3: Why do shipping companies use dimensional weight?

A. They use it to balance space usage. Large boxes with little weight still take up room in trucks and planes.

Q4: What tools should I use to measure a box?

A. A tape measure, ruler or digital caliper works best for accurate results.

Q5: Can wrong dimensions increase my shipping cost?

A. Yes, incorrect measurements often lead to higher shipping charges or rejected parcels.

Q6: What is the DIM divisor for FedEx and UPS?

A. Both usually use 139 as the divisor for domestic and international shipments.

Q7: How can Package Perfection help my business?

A. We provide wholesale packaging with accurate dimensions, free USA shipping and fast turnaround.

Q8: What if I am unsure about my box length width and height measurements?

A. Contact Package Perfection anytime. Our team is ready to guide you step by step.