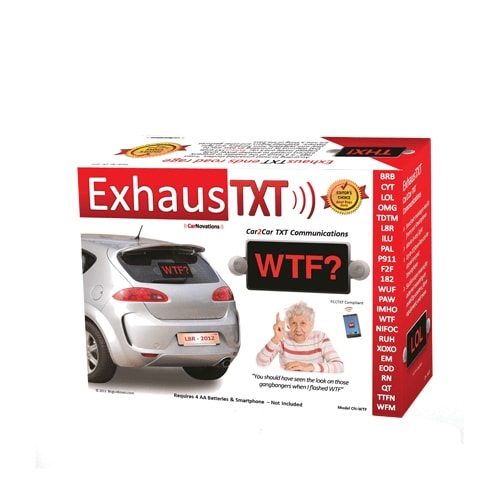

Product Boxes

There is no one-size-fits-all when it comes to packaging your retail products. Custom style product boxes are designed to meet the specific needs of your product, while also being cost-effective and readily available in a variety of shapes and sizes. With ample customization options, these boxes can also play a key role in product promotion and branding. Many leading brands have their own unique style of packaging, which not only protects the product inside but also reinforces the brand identity.

Get Free Quote

Choosing Product Packaging Boxes

Choosing the right product boxes can make all the difference for the customer experience. Nobody likes to receive a broken product, and every business wants their customers to be satisfied with their purchases. For some products, such as candles and skincare products, the packaging process is particularly challenging. Using bulky bubble cushioning or plastic peanuts is simply not sustainable.

Reverse Tuck End

Reverse tuck end on product boxes is an attractive design for packaging your products. Reverse tuck ends have bottom and top tucks that fold into the front and back panels of the box. This design is ideal for hand or machine filling. It is more economical than straight tuck ends and allows for more boxes per sheet.

Reverse tuck end product packaging boxes are often custom-printed with a logo or slogan. They can also serve as gift carriers. They are available in white color. Reverse tuck ends are available in many different sizes and shapes at Package Perfection. They can be made in a variety of finishes and can be made with a range of printing options, from simple one color to high-resolution color and full-color options.

Reverse tuck end product packaging boxes are versatile and easy to assemble. They are ideal for storing small and lightweight items. They are also easy to open and are designed for retail products. Aside from being versatile and easy to assemble, reverse tuck end product packaging boxes are also durable and reliable.

Reverse tuck end product packaging boxes are designed to be shelf ready and offer superior presentation value. These boxes are easy to open and close and feature top and bottom tuck closures. They are also easily accessible from the front or back. They are also strong enough to hold heavy items. These custom boxes can be assembled manually and have a self-locking feature.

Reverse tuck end product packaging boxes are a trendy option that is perfect for retail and product packaging. These boxes are made of cardboard or kraft and are durable enough to withstand any type of pressure. They are also very economical and easy to obtain. They are also environmentally friendly, with little to no waste.

Seal End

If you’re looking for packaging boxes to display your products, you should consider using a Seal End box. These boxes can be custom-made to fit your product line. They are available in a variety of sizes and shapes and can be printed with your brand name, logo and contact information. They also allow for solid-color printing.

Seal End boxes also provide security for inventory. A custom-printed box shows that a business takes its products seriously, increasing the value of the products. Seal end boxes also look good. They give products a more professional appearance, and can even be printed with graphics or text. Seal end boxes are especially useful for displaying information that’s important to consumers.

Another benefit of Seal End boxes is their strength and durability. These boxes are able to withstand physical impacts and harsh weather. They are also lightweight and easy to assemble. This type of packaging is incredibly versatile and makes shipping easy and effective. You can choose the size and shape that’s best for your product and budget.

Seal End of product boxes can also be used to protect fragile items. Custom-made sealed-end boxes are especially useful for medicines, candles, and glass bottles. When using these boxes, make sure to seal the ends to prevent leakage. This is the best way to ensure your items arrive in tip-top condition.

When it comes to seal end boxes, you’ll want to be sure to get one that fits your product perfectly. The wrong size can cause movement inside the box, and this could damage your products. To make sure you get the right size, you can measure the product yourself and choose the appropriate box. And if you’re not sure, you can always order custom-sized boxes if necessary.

| Dimensions | All Custom Sizes & Shapes |

|---|---|

| Printing | CMYK, PMS, No Printing |

| Paper Stock | 10pt to 28pt (60lb to 400lb) Eco-Friendly Kraft, E-flute Corrugated, Bux Board, Cardstock |

| Quantities | 100+ |

| Coating | Gloss, Matte, Spot UV |

| Default Process | Die Cutting, Gluing, Scoring, Perforation |

| Options | Custom Window Cut Out, Gold/Silver Foiling, Embossing, Raised Ink, PVC Sheet. |

| Turn Around Time | 7-10 Business Days |