Bottom Closure Boxes

Custom Bottom Closure Boxes for Strong, Hassle-Free Packaging

Looking for durable packaging that’s easy to assemble and dependable for shipping or display? Bottom Closure Boxes at Package Perfection are designed to provide reinforced structure and effortless use, ideal for both retail and industrial packaging.

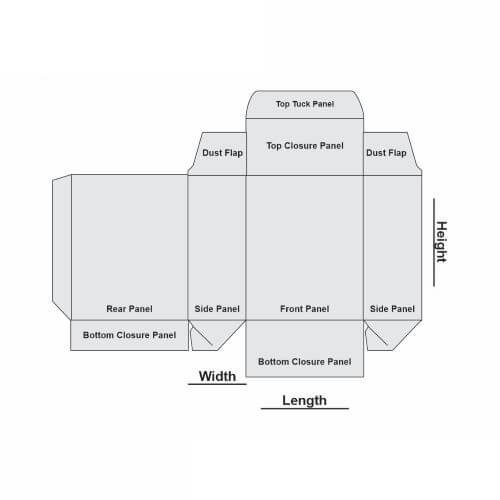

Our collection includes various styles such as:

-

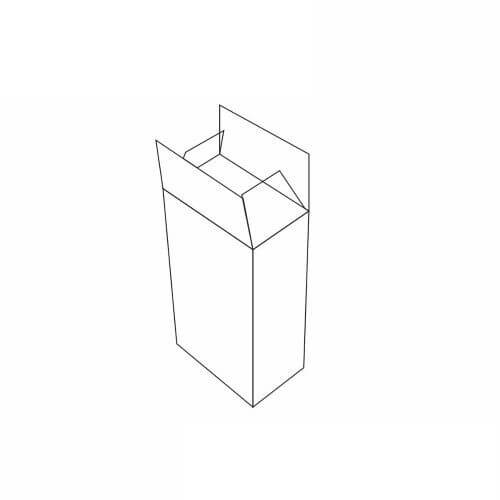

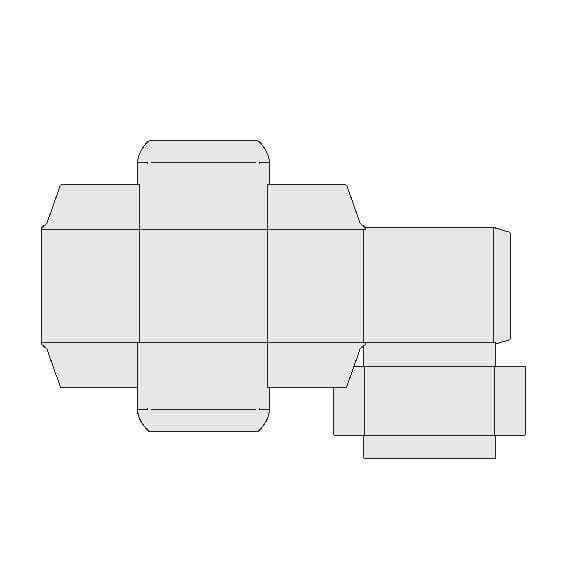

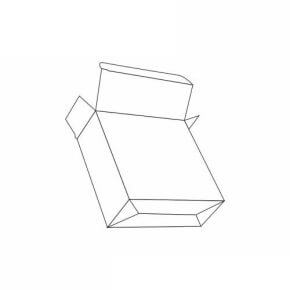

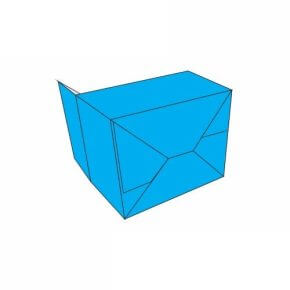

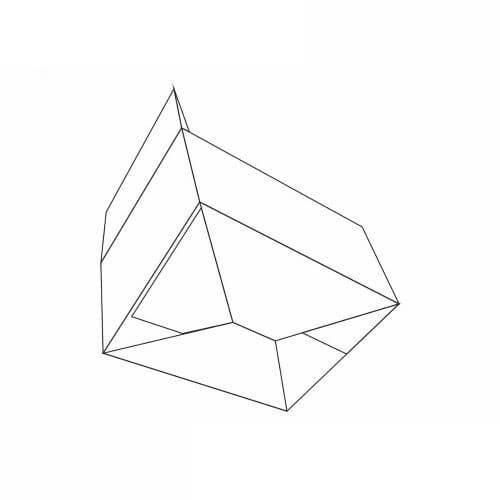

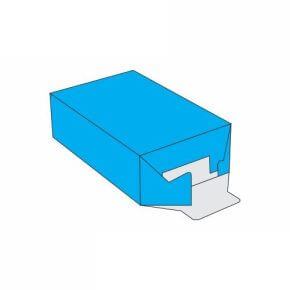

Custom 1-2-3 Bottom Boxes: Perfect for heavier items. Features interlocking flaps for added bottom strength and easy manual assembly.

-

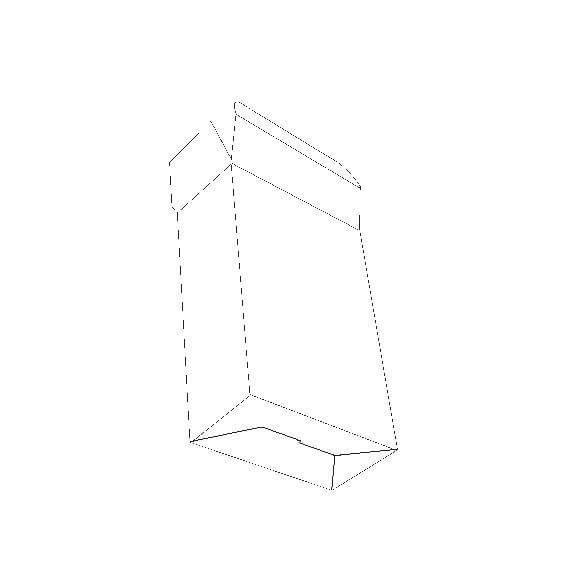

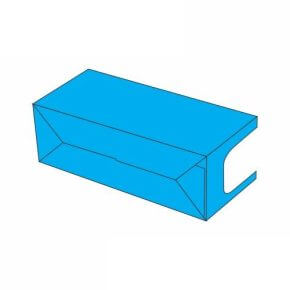

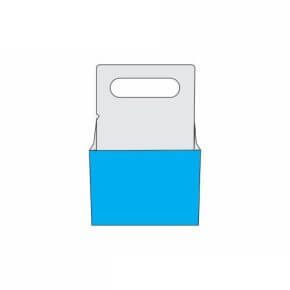

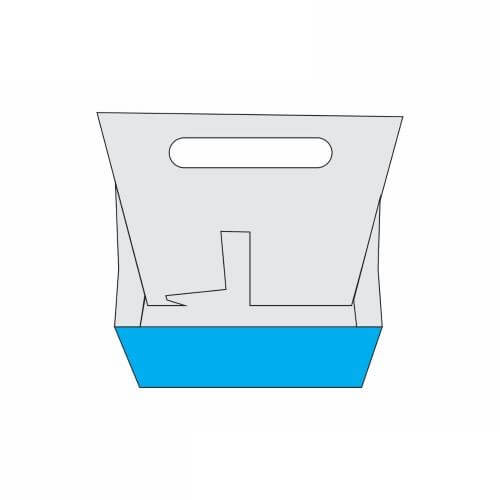

4 Pack Bottle Carrier: Designed to carry four glass or plastic bottles securely, commonly used for beverages or cosmetics.

-

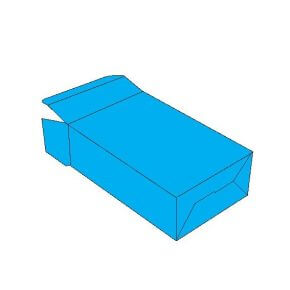

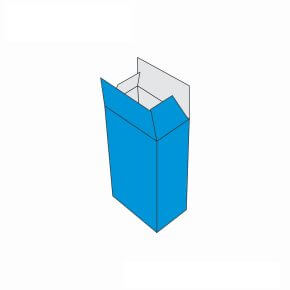

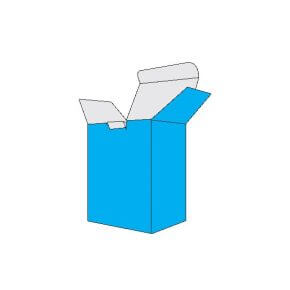

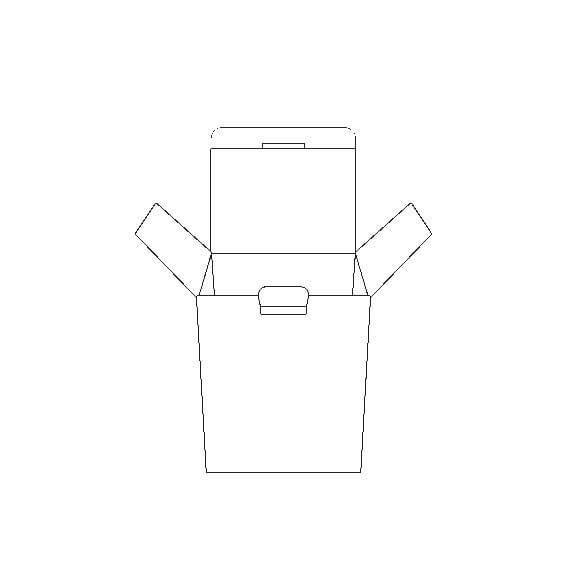

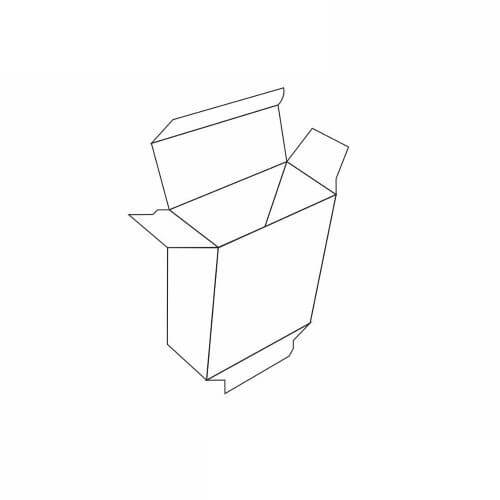

Tuck Top Auto Bottom Boxes: A favorite for quick assembly; just push and the bottom automatically snaps into place.

-

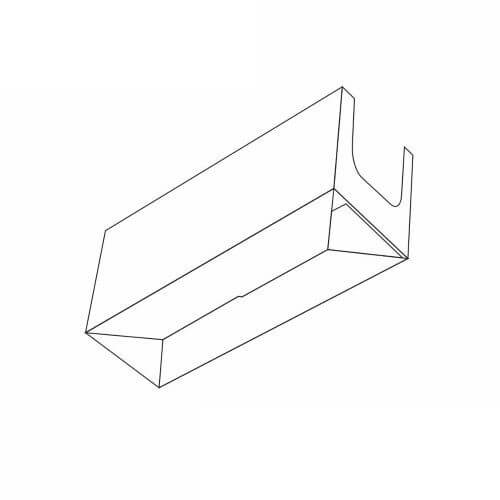

Auto Bottom Tray: Offers pre-glued bottom flaps and an open tray-style top—best for organized product display or fast fulfillment.

Each box is crafted from high-quality corrugated or cardboard materials, fully customizable with your brand’s logo, design, or product information. These boxes are especially popular among retailers, subscription services, bottle manufacturers, and cosmetic brands.

Why Choose Package Perfection?

-

Best Pricing in the Market: Competitive rates for all box styles.

-

Bulk Deals: Special discounts on large orders.

-

Flexible Customization: Available in all sizes, colors, and finishes.

-

Fast Turnaround & U.S.-Based Shipping: Quick delivery with no hidden charges.

Whether you're shipping delicate glass bottles or preparing a product for retail shelves, our Bottom Closure Boxes ensure stability, safety, and a professional look. Choose from glued or manual bottom lock options based on your assembly preferences and product weight.

Get started with packaging that’s reliable, custom-fit, and cost-effective, only at Package Perfection.