Edible Packaging

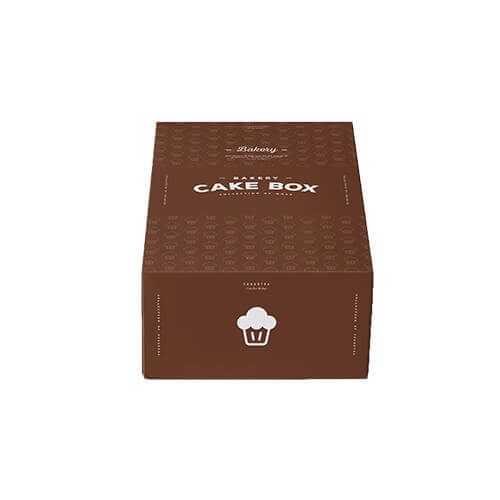

Custom edible packaging is essential for product safety and brand recognition. Different sizes, shapes, styles, and designs are available to suit the packaging needs of the respective edible product. These packages are manufactured from high-quality Kraft paper and cardboard materials known for their sturdiness and excellent capabilities to keep the packaged items original in taste and quality.

Get Free Quote

Custom Edible Packaging

Edible Packaging is a term that describes packaging materials that are biodegradable and edible. This type of packaging is a greener alternative to traditional plastic packaging. However, it is important to understand the manufacturing costs and the risks associated with using this type of material. Also, consider the market growth of this type of packaging.

Ingredients in Edible Boxes

When choosing edible packaging, it’s important to consider the needs of both the consumer and the product. Ideally, the packaging should have the desired effect on both aspects, without sacrificing the taste of the product. In order to achieve these goals, edible Boxes is typically made of several components that balance each other’s needs. In this article, we’ll discuss the advantages and disadvantages of using edible Boxes for different products.

One type of edible Boxes is made from milk proteins, which are used to form a casing around the product. This material is more effective at blocking oxygen than plastic. It has a plastic-like appearance but does not have the taste of plastic. Some manufacturers also add citrus pectin, which makes the packaging stronger. This type of packaging is an alternative to disposable plastic. This type of packaging is a great option for food packaging.

Another option is edible rice paper. Asian rice candy is often sold in edible rice paper packages. This type of packaging protects the food from the environment, while the outer layer is made of wax paper or plastic. Either option provides food protection from contaminants and a convenient way to consume the product.

Manufacturing Materials

These products are made from a variety of materials including proteins, lipids, and polysaccharides. These materials are considered safe for human consumption, but the high cost of manufacturing them will hamper the market’s growth.

Manufacturers are focused on the development of edible packaging that can be used for different applications. These products can be used as containers or wrapping paper and can even be used in place of plastic sachets. These packages are designed to preserve the taste and quality of food products. While edible packaging is environmentally friendly, the cost of manufacturing it is high.

To reduce manufacturing costs, food companies can source their raw materials from natural sources, such as seaweed and algae. These sources don’t pose environmental concerns, and they can be grown and harvested with minimal resources.

Growth of the edible packaging market

In recent years, the market for edible Boxes has been growing. The trend can be attributed to several factors. For example, edible packaging decreases the amount of waste that goes into landfills and increases the shelf life of the product. Growing environmental concerns are projected to fuel the market for edible packaging. Furthermore, these products can also be used for more than one purpose. The report highlights the latest trends in the market. It also provides market size and forecasts for the global and regional level. It also highlights the key market drivers and restraints as well as opportunities. The report also examines the competitive landscape of the edible packaging market, including the threats of substitutes, new entrants, and the strength of buyers.

| Dimensions | All Custom Sizes & Shapes |

|---|---|

| Printing | CMYK, PMS, No Printing |

| Paper Stock | 10pt to 28pt (60lb to 400lb) Eco-Friendly Kraft, E-flute Corrugated, Bux Board, Cardstock |

| Quantities | 100+ |

| Coating | Gloss, Matte, Spot UV |

| Default Process | Die Cutting, Gluing, Scoring, Perforation |

| Options | Custom Window Cut Out, Gold/Silver Foiling, Embossing, Raised Ink, PVC Sheet. |

| Turn Around Time | 7-10 Business Days |