Blister Cards

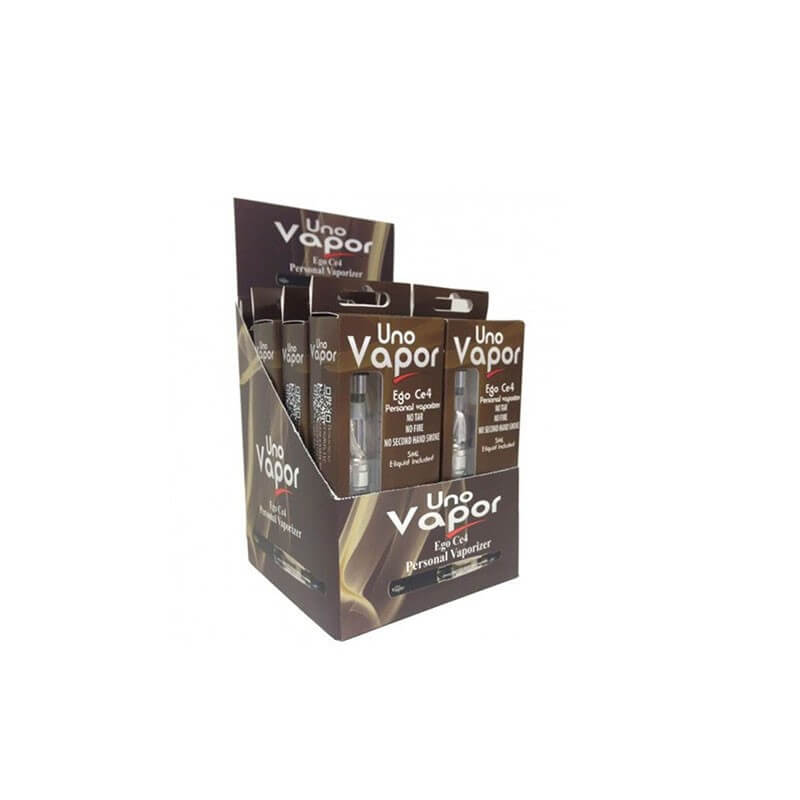

Differentiating your product from the competition is essential for success in any market. One way to make your product stand out is by using blister card packaging – a cost-effective and easy-to-implement solution that can have a significant impact on shelf appeal. Blister cards offer several advantages over alternative packaging types, including increased tamper resistance and a more eye-catching presentation.

Get Free Quote

Blister Cards

When it comes to blister cards packaging, there are several different methods to choose from. These include heat-sealing, flexographic printing, Cyclic olefin copolymer resins, and plastic sheeting. However, some manufacturing methods are less expensive than others.

Plastic sheet

Blister cards are a popular type of packaging for certain products, including food, toys, electronics, and tools. The packaging is typically made of a rigid plastic sheet with backing and adhesive that allows the product to be slid into the blister. Because the packaging is made of a single sheet of plastic, it is easy to create and print on. However, there are some special considerations when it comes to the design and optimization of blister cards.

The process of a blister pack starts with a plastic sheet that is fed into a preheating station where it is heated slightly above the plastic’s glass transition temperature. This step is necessary in order to make the plastic soft and malleable before it is transferred to a forming station. The forming station applies large pressure (usually 4 to 8 bars) to form the blister cavity into a negative mold. Once the plastic is cooled, it regains its rigidity. This process is crucial to the successful completion of the blister card manufacturing process.

When it comes to choosing the right plastic sheet for blister packaging, it is important to consider the material’s thickness and other factors. The ideal thickness for blister packaging is between 200u and 300u. However, this will depend on the shape and size of the blisters. For instance, most pharmaceutical blisters are made with a 250u PVC sheet, which is about 0.250 mm thick. This thickness can withstand approximately 20 mL of fluid per square meter.

Heat-sealing

Heat-sealing blister cards are a versatile, cost-effective packaging solution. Using one piece of board with a heat seal coating, blister cards can be printed on one or both sides. They are a popular packaging solution for retail products due to their flexible design, high visibility, and full protection.

Heat-sealing blister cards utilize a combination of pressure, temperature, and dwell time to seal a product. The standard sealing conditions are 350F to 375F, 50-60 PSI, and two to three seconds dwell time. Higher temperatures and longer dwell times are needed for thicker paperboards. Some forms of heat sealing also entail the use of a plastic cell as a heat source, so a heat sealer may require multiple passes.

The process of heat-sealing allows blister packs to be tightly sealed, discouraging in-store opening attempts. It also simplifies the opening process for consumers. Heat-sealing blister packs are ideal for paperboards with fold-over edges. Some two-part paperboards can be as thick as 32 points, which are naturally tear-resistant.

| Dimensions | All Custom Sizes & Shapes |

|---|---|

| Printing | CMYK, PMS, No Printing |

| Paper Stock | 10pt to 28pt (60lb to 400lb) Eco-Friendly Kraft, E-flute Corrugated, Bux Board, Cardstock |

| Quantities | 100+ |

| Coating | Gloss, Matte, Spot UV |

| Default Process | Die Cutting, Gluing, Scoring, Perforation |

| Options | Custom Window Cut Out, Gold/Silver Foiling, Embossing, Raised Ink, PVC Sheet. |

| Turn Around Time | 7-10 Business Days |